Features

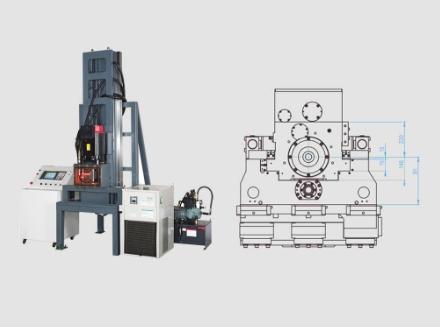

Optimal Spindle Head Layout

- The spindle center line closes to z-axis slideways, greatly reducing the possibility of thermal displacement and bending deformation due to side cutting torque.

-

Driven by a powerful motor, the spindle head is ideal for various complicated machining with ultra-high accuracy.

-

Spindle gearbox is designed as rectangular in cross-section and its structure is symmetrical closed. It ensures the spindle gear box symmetrical heat conduction and preventing thermal distortion and minimizing defection.

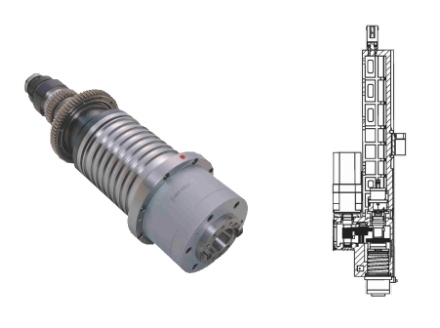

Two-step Speed Gearbox

-

The spindle running is transmitted through a gearbox, providing high/low speed changes.

-

The spindle running is transmitted through a gearbox, providing high/low speed changes.

-

All gears in the gearbox are carburized and precision ground for quiet running.

Spindle Oil Cooler

-

The spindle oil cooler can adjust to appropriate temperature to control the spindle accordingly and properly.

-

The cooler provides excellent cooling feature for gears, stabilizes the precision of the spindle, and extends the lifetime of the spindle and gearbox.

Hydraulic & Nitrogen Gas Dual Counter-balancing System

The spindle oil cooler can adjust to appropriate temperature to control the spindle accordingly and properly.

-

The nitrogen gas counter-balancing system is equipped with an accumulator, and no additional power unit is required.

-

Features no noise and no vibration.

-

It ensures extra smooth movement of the spindle head for increased machining accuracy.

Cutting Capacity

Face Milling

| Cutting tool | Ø125 x 8t |

| Tangential speed | 295.35 m/min |

| Cutting width | 120 mm |

| Cutting depth | 4 mm |

| Cutting feed rate | 140 mm/min |

| Cutting amount per tooth | 0.27 mm |

| Material removal rate | 756 mm |

| Workpiece material | S45C |

| Spindle load | 80% |

*Note: The above cutting test values are for reference only. The values may vary with customers cutting conditions.

Drilling

| Tool diameter | Ø90 mm |

| Tool material | Tungsten Carbide |

| Cutting depth | 100 mm |

| Cutting feed rate | 5 mm/min |

| Workpiece material | SUS304 |

| Spindle load | 48% |

*Note: The above cutting test values are for reference only. The values may vary with customers cutting conditions.

End Milling

| Cutting tool | Ø32 x 8t |

| Tangential speed | 158.6 m/min |

| Cutting width | 6 mm |

| Cutting depth | 20 mm |

| Cutting amount per tooth | 0.21 mm |

| Material removal rate | 187 cc/min |

| Workpiece material |

S45C |

| Spindle load |

65%

|

*Note: The above cutting test values are for reference only. The values may vary with customers cutting conditions.

Specifications

Standard Accessories

- Fanuc control system

- Halogen work light

- Controller operation manual and electric circuit drawing

- Operation and maintenance manual

- Service tool

- Leveling bolts and blocks

- RS-232 interface

- Program finished warning lamp

- Automatic power-off device

- Air gun for removing chips

- Forced automatic lubrication system

- Air system

- Z-axis hydraulic counter-balancing system

- Nitrogen gas counter-balancing system

- Spindle oil cooler

- Coolant pump and tank

- Crawler chip conveyor with chip bucket

- Ship augers (at both sides)

- Semi-enclosed splash guard

- Machine accuracy inspection report

Optional Accessories

- Auxiliary tool stand

- NC rotary table

- Automatic tool setting device

- Computerized scanning imitative system

- Liner scale feedback

- 90° side milling head

- Universal milling head

- 45° angular milling head

- Oil water separating tank

- Coolant through spindle