Planning Process

Seamless Collaboration, Tailored Excellence: Elevating Partnerships Through Adaptable Innovation.

Advantages of Our Planning Process

Leverage Existing Machine Models

Utilize the versatility of our current machine models as a foundation for both ODM and OEM projects, ensuring a robust starting point for customization.

Client-Centric Collaboration

Engage in collaborative discussions with clients to understand their specific requirements, and adapt our machine models accordingly.

Adaptive Features and Functionalities

Employ a flexible approach to adapt features, specifications, and functionalities of existing machine models to align with the unique needs of each ODM and OEM project.

Experienced Team Involvement

Our experienced team, well-acquainted with our machine models, plays a crucial role in crafting detailed plans that seamlessly integrate client specifications.

Streamlined Production Approach

Implement a streamlined production process that capitalizes on the efficiency and reliability inherent in our machine models, accelerating project timelines.

Quality Assurance Standards

Uphold rigorous quality assurance standards throughout the planning and production stages to ensure that customized ODM and OEM solutions maintain the high quality synonymous with TopOne Machinery.

Continuous Innovation

Drive continuous innovation by incorporating client feedback and staying abreast of technological advancements, ensuring our machine models evolve to meet the dynamic demands of diverse industries.

R&D

Innovating Manufacturing Futures: TopOne Machinery's R&D Excellence in ODM and OEM

Great stories have a personality. Consider telling a great story that provides personality. Writing a story with personality for potential clients will assist with making a relationship connection. This shows up in small quirks like word choices or phrases. Write from your point of view, not from someone else's experience.

Strategic R&D for ODM and OEM Models

Our Research and Development (R&D) initiatives for ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing) are strategically grounded in the foundation of our existing machine models. With a robust portfolio of machinery, our R&D endeavors focus on enhancing and expanding the capabilities of our current models to meet the evolving demands of customization.

Strategic R&D for ODM and OEM Models

Our dedicated R&D team collaborates closely with clients to understand their unique requirements, leveraging the versatility of our machine models as a springboard for innovation. This involves exploring adaptive technologies, refining features, and incorporating cutting-edge functionalities that align seamlessly with the specific needs of ODM and OEM projects.

Exceeding Expectations: TopOne Machinery Solutions

The goal is to not only meet but exceed client expectations, ensuring that our machine models serve as dynamic platforms for tailored solutions. By infusing our R&D efforts with adaptability and ingenuity, TopOne Machinery remains at the forefront of technological innovation, ready to shape the future of manufacturing.

Manufacturing Capacity

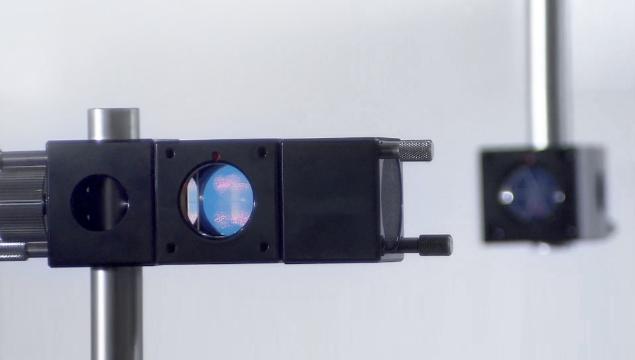

Precision in Motion, Innovation in Every Detail

Great stories have a personality. Consider telling a great story that provides personality. Writing a story with personality for potential clients will assist with making a relationship connection. This shows up in small quirks like word choices or phrases. Write from your point of view, not from someone else's experience.

Precision-Powered Manufacturing Capacity

At TopOne Machinery, our manufacturing prowess is anchored in a robust combination of advanced machine models and cutting-edge equipment designed to enhance our machining capabilities. Our diverse range of machine models forms the backbone of our manufacturing capacity, providing versatility and precision to cater to an array of industry needs.

Innovative Excellence in Machining

Additionally, we invest strategically in state-of-the-art equipment to augment our machining abilities. These enhancements include advanced CNC systems, precision tools, and innovative technologies that empower our team to deliver exceptional results. By synergizing our extensive machine models with top-tier equipment, we not only meet but surpass industry standards.

Efficiency and Reliability Leaders

This integrated approach ensures that TopOne Machinery remains a leader in manufacturing capacity, offering clients unparalleled solutions with a commitment to efficiency, reliability, and continuous advancement.

Quality

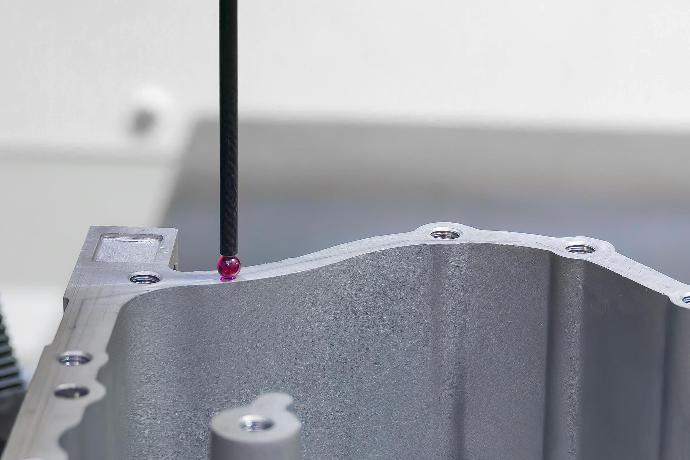

Sculpting Excellence, Ensuring Precision: Our Commitment to Unyielding Quality Standards.

Great stories have a personality. Consider telling a great story that provides personality. Writing a story with personality for potential clients will assist with making a relationship connection. This shows up in small quirks like word choices or phrases. Write from your point of view, not from someone else's experience.

Meticulous Quality, Unmatched Commitment

Quality control is the bedrock of our manufacturing ethos. Our commitment to delivering excellence is reflected in the meticulous processes integrated into every stage of production.

Rigorous quality checks commence from the initial design phase, where our experienced team ensures that each component meets stringent specifications.

Elevating Standards with Precision Tools and Tech

Throughout the manufacturing process, cutting-edge inspection technologies and precision tools are deployed to guarantee the highest standards. Our dedicated quality control team conducts thorough assessments, from dimensional accuracy to material integrity, ensuring that each product leaving our facilities adheres to the uncompromising benchmarks set by TopOne Machinery.

Trusted Precision for Unwavering Excellence

This unwavering focus on quality not only underscores our dedication to customer satisfaction but also positions us as a trusted and reliable partner in the realm of precision machining.