Features

Beam Clamping

- The beam is clamped securely by hydraulic force in combination with the use of dise springs. This fully prewents the beam from slipping down to eliminate any loss in grinding accuracy.

Beam Elevation

- The beam elevation is driven by an inverter controlled motor that drives a connecting shaft to transmit the two elevation gcrews at the left and right sides. This elevation driving system allows the beam to clovate synchronously at both ends, so as to ensure outstanding leveling accuracy of the beam.

Double Hydraulic Cylinders' Counter-balance

- The beam elewation (Z-axis) is counters balanced by two hydraulic cylinders, enguring exceptionally smooth motion sand the best travel accuracy.

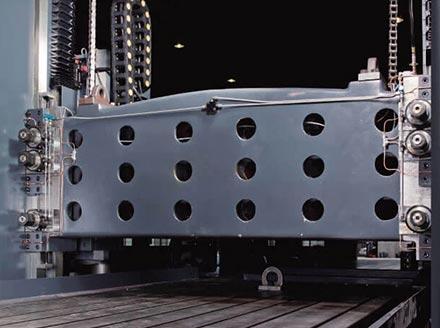

Horizontal Grinding Head (Standard)

- The Top-One GL series Double Column Surface Grinding Machine can be mounted with a horizontal grinding head and a vertical grinding head, allowing surface grinding and angular grinding to be accomplished at a time. With both grinding heads, the increased grinding accuracy and afficiency can be achieved.

Specifications

Standard Accessories

- Grinding wheel calibrating device(Balancing Stand)

- Diamond dresser

- Magnetizer

- Wheel balancing arbor

- Horizontal/Vertical grinding wheel

- Flange(1 set)

- Heat exchanger for electrical cabinet

- Hydraulic oil cooler

- Paper filter(including filtrating paper and coolant tank)

- Voltage stabilizer

- Tool box with tools

- Operation and maintenance manual

- Operation Manual

- Vertical grinder automatic angle positioning(std.)

Optional Accessories

- Automatic angle positioning device for vertical grinding head

- Vertical grinding head

- Grinding wheel

- Increased spindle speed

- Increased spindle horsepower

- Automatic wheel dresser for vertical grinding head

- Movable swiveling function

- Fanuc control

- Mitsubishi control

- Spared wheel flange set for vertical grinding head

- Spared wheel flange set for horizontal grinding head

- Transformer